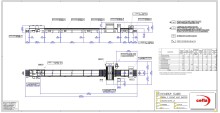

Automatic through feed spraying machine with 2 reciprocators

in a large size pressurised booth with one combined

self-cleaning and reclaiming device for the overspray on the

belt.

Machine arranged for installation of one additional lacquer

reclaiming unit.

Main technical data:

Total machine length 5.680 mm

Total machine width 3.980 mm

Total machine height 2.800 mm

Distance between reciprocators 1.780 mm

Conveyor speed 3 - 9 m/min

Working height 900 +/- 20 mm

Installed power 22,6 kW

Compressed air connection 6 bar

Air consumption (indicative value with 12 airmix guns) approx

2.800 Nl/min

Exhaust 9.500 mc/h

Control side: Right hand (unless otherwise specified)

Colour: RAL 9002

The machine consists of:

In-feed roller conveyor with inverter controlled drive motor;

photocell reading bar system for the detection of the

dimensions, position and shape of the incoming work-pieces;

Technical data:

Conveyor length 1.450 mm

Working width 1.300 mm

Roller diameter 64 mm

Roller pitch 125 mm

Reading accuracy: 10,4 mm

Belt conveyor in the spray area

Closed belt conveyor system mounted on a open structure for

easy removal and maintenance of the belt.

Belt conveyor in special material able to work with all kind of

paint and stains.

Transparent cover on the outfeed extension of the conveyor.

Patented combined lacquer recovery system, with two units of

steel chromium plated rollers and cleaning blades, for recovery

and cleaning of the conveying belt mounted on trolley.

Feed speed adjustment through inverter controlled drive motor.

Technical data for the conveyor:

Conveyor length 4.230 mm

Belt width 2.000 mm

Spraying width 1.600 mm

Useful width 1.300 mm

Lacquer application system with double reciprocator, driven by

brush-less motor and sliding on precision guides. The two

reciprocators are mounted over the filtering roof to prevent any

dust contamination.

Two spray arms, each one equipped with guns holder

through the roof move cross-wide the spray area.

Three high pressure paint circuits (with possibility to install up to

six paint circuits).

Technical data:

Motor power 9 kW

Reciprocator stroke 2500 mm

Reciprocator max speed 27 cycles/min.

Large size pressurised spray booth in welded and painted steel

framework, with access doors to the spray room on both side.

High performance pressurisation system consisting of

pre-filtering unit, two centrifugal blowing fans, distribution

plenum and filtering roof inside the cabin for fine cleaning of the

air.

Exhaust system with sequence of double stage dry filters and

exhaust ventilator.

Inverter control of the air inlet ventilators to adjust the booth

pressure.

Flameproof lighting system inside the spray cabin.

Machine executed according to the European norms, suitable to

be used with solvent-based lacquers.

The correct use of the machine allows to keep the area with risk

of explosion (Zone 2) inside the machine.

Electronic control on PC placed on control cabinet withsupporting no. 8 spray guns (guns not included in the supply),

Windows-based software.

Operator-friendly graphic interface for the setting of all working

parameters and machine parameters.

Easy manage of the machine by production report, diagnostic

and trouble shooting procedure.

Different machine set-up can be saved on the hard-disc as

working programs.

Independent control of each spray gun, for the individual set-up

of the gun opening/closing in agreement with the conveying

speed and the size/shape of the panels.

The electronic control is mounted on the control switchboard

(non Eex-execution), which includes all necessary electrical and

electronic components for the functioning of the machine,

including 6 meters of connection cable to the machine.

7651 One set of additional gun holders with quick change device type

"SUPERFICI" (patended).

7650 One set of quick change device for gun holders type

"SUPERFICI" (patented).

7619 Additional combined lacquer recovery and belt cleaning system

blades, mounted on trolley.

Including all electrical and pneumatical controls.

7675 Modem + PC anywhere for the remote control with two units of steel chromium plated rollers and cleaning