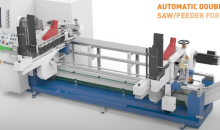

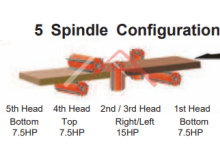

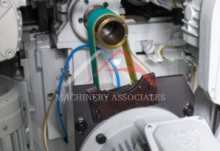

New Northtech Five Spindle Moulder

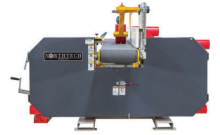

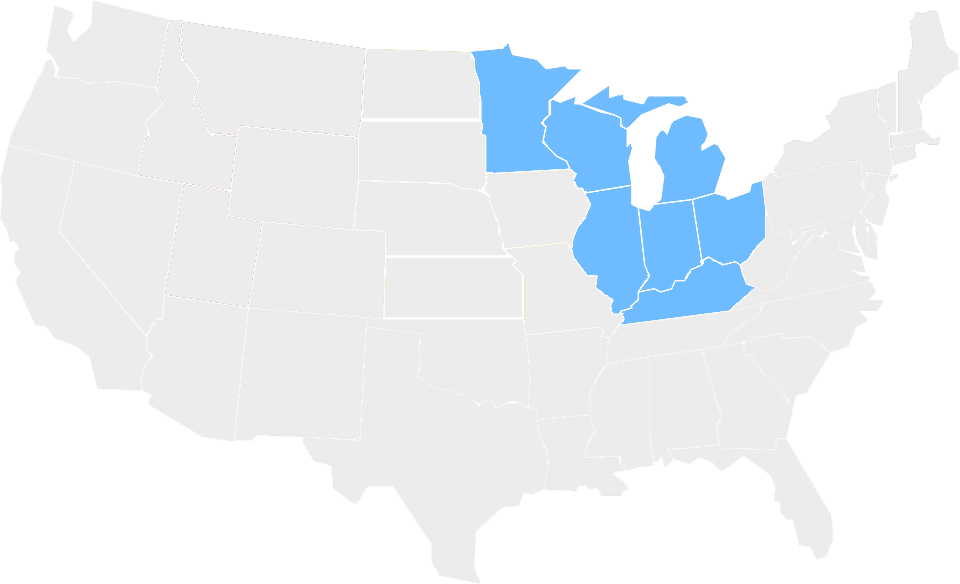

New Northtech Five Spindle Moulder With A 3HP Feeder. Machinery Associates is a full line Northtech Dealer.

| MA ID: | MFT - 13153 |

| Price: | Call for Price |

| Category: |

Moulder - Feed Through |

| Manufacturer: | Northtech |

| Model: | NT S5230 |

| Year of Manufacture: | New |

| Condition: | New |

| Electric: | 230 Voltage 60 Cycle 3 Phase |

|

Northtech Moulder

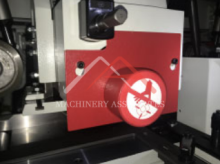

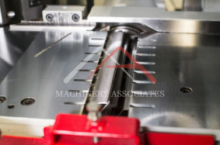

Specifications: SPINDLE ARRANGEMENT: FEED SYSTEM: PRODUCT DIMENSIONS: FEATURES: Infeed table length: 51" Hard chrome plated table Incorporated bed roller (2) 4 Wing 5" x 9", corrugated knife stock moulder heads for 40mm (Included) (2) 4 Wing 5" x 4", corrugated knife stock moulder heads for 40mm (Included) (1) 5" x 9" Helical cutterhead with (2) sided 30x12 carbide inserts Warranty is one year parts 1 Day Start Up & Training included, travel expenses not included. Options: FEED MAGAZINE: • This feeder provides maximum convenience for feeding SPINDLE DIGITAL POSITIONING CONTROLLER: INFEED SIDE PRESSURE ROLLERS: FIRST VERTICAL SPINDLE SIDE PRESSURE ROLLERS: SPINDLE BRAKES: BED PLATE OILER: POP UP INFEED: LOW AIR ALERT: PNEUMATIC SHOES: PNEUMATIC CHIP BREAKERS:

|

|

| Shipping Footprint: |

102 (length) x 56 (width) x

76 (height)

|

| Weight: | 6900 lbs |

Some photos may show tooling. Tooling is never included in the listing unless otherwise noted in the description.

Please confirm all data before committing to a purchase.

*Subject to credit approval. Additional programs available.