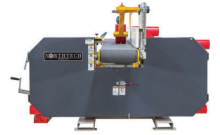

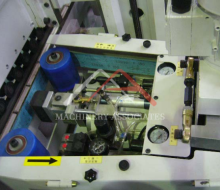

New Northtech NT PS100-4B PROFILE SANDER

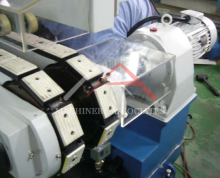

Dual Feed Chains Feed System And PLC Setting Controls. Machinery Associates is a full line Northtech Dealer.

| MA ID: | SPM - 13128 |

| Price: | Call for Price |

| Category: |

Profile/Moulding |

| Manufacturer: | Northtech |

| Model: | NT PS100-4B |

| Year of Manufacture: | New |

| Condition: | New |

| Electric: | 230 Voltage 60 Cycle 3 Phase |

|

Northtech Profile Sander

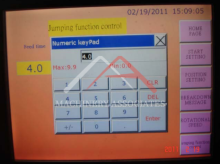

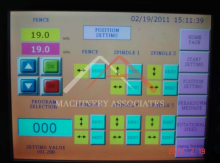

Specifications: Single End Tenoner style Profile Sander incorporates a solid cast iron base providing high Dual feed chains system approximately 8” on center with precision reference fence, pads, and 1/2” x 1/2” dogs with 16” spacing. Chain dogs are spring loaded style and require only a push downward and a 90° rotation to lock out A powered single pressure belt hold down system is a standard feature and incorporates Upper pressure belt and secondary free wheel hold downs above the outside chain are Dual transport chain and pads are driven by a 3HP feed motor mated to a 5HP inverter Feed speed is 12-60 FPM and incorporates a jog control pendant for initial positioning of All (4) belt stations are arranged with a 3HP motor, 30mm to 80mm W x 2070mm sanding belt with Abrasive belt station incorporates a pneumatic control adjustment to allow the belt to float or Programmable PLC touch screen controls allows storage of up to 99 programs covering Infeed fence system with digital readout is arranged with dual linear bearings and rails. It A hand held controller with jog and stop are included for improved set up and testing procedures. An automatic air blow off device with timer is included to help maintain the cleanliness of Bottom beam length is 126” and is made of high grade cast iron and CNC milled for optimum All electrical components employed are both UL and CE approved including motors, electric |

|

| Shipping Footprint: |

174 (length) x 66 (width) x

60 (height)

|

| Weight: | 8500 lbs |

Some photos may show tooling. Tooling is never included in the listing unless otherwise noted in the description.

Please confirm all data before committing to a purchase.

*Subject to credit approval. Additional programs available.