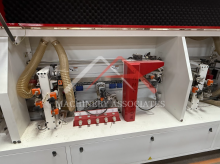

Vantedge MM 6.5 Edgebander

Smokin deal on a late model edgebander

| MA ID: | EBS - 14437 |

| Price: | $59,900.00 |

| Category: |

Edgebanders -Single Sided |

| Manufacturer: | OTHER |

| Model: | Vantedge MM6.5 |

| Year of Manufacture: | 2021 |

| Condition: | Very Good |

| Electric: | 230 Voltage 60 Cycle 3 Phase |

|

2021 Vantedge MM6.5 Edgebander

Specifications: Working Capacity Edgebanding thickness 0.4 - 3 mm coil stock capacity & 10 mm strip capacity. Min. panel width 85 mm (3.3") Min. panel length 125 mm (4.9") Panel thickness 10 - 60 mm (0.39" - 2.36") Tape and Panel Infeed System: 750 mm Coil support table; Adjustable feed speed 14, 16 & 20 MPM (66 FPM). Digital adjustment for the Premill Top Pressure Beam Adjustment: Automatic adjustment from the PLC control Pneumatic Pop-Up Stop system. Red LED panel feed indicator light for correct panel spacing. Equipped with: Misting unit prior to Pre-milling; Dual 3 HP Counter-rotational Pre-milling motors w/diamond cutter heads w/pneumatic "JUMP In/Out function. Quick change Glue Reservoir Pressure Section/Infrared Heat Lamp System. Heavy-Duty automatic shear type Guillotine with: "Auto-Set" automatic intervention for strip & coil materials. (4) Pneumatic polished Pressure Rollers with manual digital adjustment to edge thickness. (1) Rubber infeed Tape Roller, (1) metal infeed Tape Roller; direct Universal Drive system - NO Chains. Teflon-coated glue pot; digital thermostats with automatic kick down when at idle. Workstations: End Trimming Unit: Dual 0.5 kW (0.67 HP) high frequency End Trim motors on precision "Auto Lube" Linear Guideways; 90° to 10° pneumatic tilt cut adjustment. Electronic sensors to safely monitor motor positions; thumb screw pneumatic adjustments for simplicity. Tilting Super Finish Top & Bottom Trimming Station: Dual High Frequency 0.65 kW (0.75 HP) motors with Combi Finish insert tooling.Top Servo driven positioning of motors for different edge trimming profiles & positions. Corner Rounding Unit: Motors on precision billet aluminum swing tracer arms with pneumatic guidance and Face Copy System. (2) Independent motors can be adjusted to match tape thickness via digital scales. Profile Scraping Unit: Top, bottom & side Copy Wheels to properly follow your panels edge. Panel Nesting System: Triple Copy Wheel System for panels with blind dados & hinge cup holes. Digital adjustment for fine-tuning the unit to the proper tape thickness. Flat Scraping Unit: Large copy wheels. Buffing Unit: Top & bottom Buffing Unit; 0.5 HP (0.37 kW) - 2,800 RPM motors; units tilt 0° - 30°. Dual Hot Air Blowers: To re-embellish edge materials. Operator Interface 10" Color touchscreen PLC with swivel Control Panel. T he PLC controls all working units & the adhesive thermostats with 1-touch icon programmable selections. Photo indicator alarms to easily troubleshoot errors/issues Extra Gluepot and cleaning station included.

Return conveyor is for sale separately |

|

| Shipping Footprint: |

25 (length) x 5 (width) x

6 (height)

|

| Weight: | 7500 lbs |

Some photos may show tooling. Tooling is never included in the listing unless otherwise noted in the description.

Please confirm all data before committing to a purchase.

*Subject to credit approval. Additional programs available.