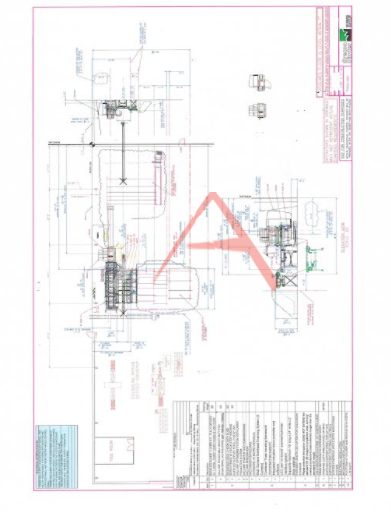

RAIMANN VARIORIP KM310 2M WITH TIMBERMAX INFEED SYSTEM

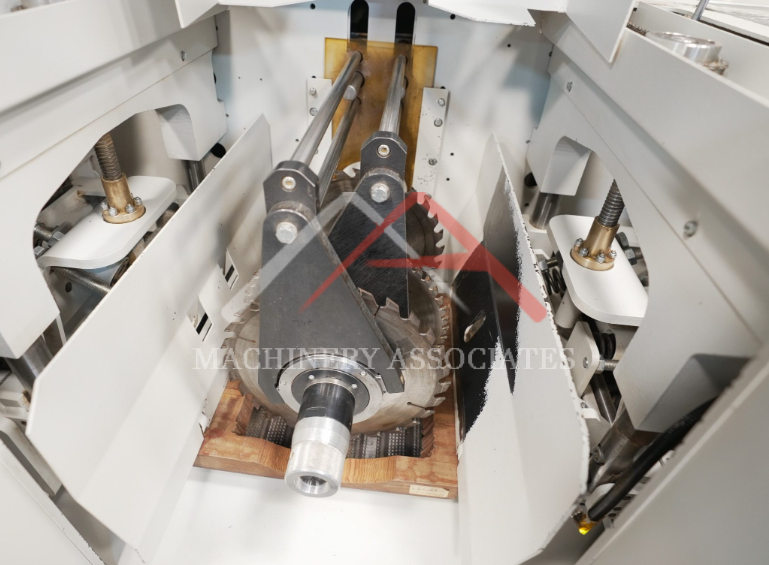

GREAT CONDITIONED SAW 6-7 BOARDS PER MINUTE. GREAT CHAIN AND LOW HOURS

| MA ID: | RGR - 13905 |

| Status: | Sold |

| Price: | Call for Price |

| Category: |

Rip Saw - Gang (multi blade) |

| Manufacturer: | Raimann |

| Model: | KM310 2M WITH TIMBERMAX INFEED |

| Year of Manufacture: | 2015 |

| Condition: | Very Good |

| Electric: | 460 Voltage 60 Cycle 3 Phase |

| Hours on meter: | low |

|

GREAT LATE MODEL SAW COMBO WITH TIMBERMAX INFEED. IMPROVE EFFICENCY WITH LESS HANDS ON.

Working dimensions: Cut width 12-1/4”; 13-3/8” with movable blades and pass through width of 31-1/4”. Arbor: RAIMANN “QUICK FIX” arbor with two (2) movable blades and one fixed. Dia. 3.14”. Motor: 50 HP Saws: Depth of cut with movable blade 3-1/2” with pressure shoe; 4-4/8” with out pressure shoe. Chain: 13-3/8" wide; Oil lubricated with “auto shut”: spikes every 3rd link. Pressure rollers: (4) total with protection against kickback to operator. Blade positioning: (2) multifinctional joysticks; (1)for each movable blade. Auto fence positioning for standard widths. Feed speed: Up to 157 FPM Chain: 13-3/8" wide; Oil lubricated with “auto shut”: spikes every 3rd link. Pressure rollers: (4) total with protection against kickback to operator. RAIMECH E5 Infeed system for untrimmed and unedged boards. Infeed: Conveyor 48” x 16’0”. The operator positions the board for the “best” optimization. Auto-Fence positioning for standard widths, lasers position for maximum yield. TIMBERMAX 3.0 Optimizing Software 3.0 Optimization Software: Optimizes throughput vs. yield, value added and production amounts. Calculation based on widths, quality of board and price yield based on operators input. All production data is recorded. Includes: Blades and spacers. RAIMECH E5 Infeed system for untrimmed and unedged boards. Infeed: Conveyor 48” x 16’0”. The operator positions the board for the “best” optimization. Auto-Fence positioning for standard widths, lasers position for maximum yield. TIMBERMAX 3.0 Optimizing Software 3.0 Optimization Software: Optimizes throughput vs. yield, value added and production amounts. Calculation based on widths, quality of board and price yield based on operators input. All production data is recorded. Blade positioning: (2) multifinctional joysticks; (1)for each movable blade. Auto fence positioning for standard widths.

|

|

| Shipping Footprint: | Full Truck |

| Weight: | 10000 lbs |

Some photos may show tooling. Tooling is never included in the listing unless otherwise noted in the description.

Please confirm all data before committing to a purchase.

*Subject to credit approval. Additional programs available.