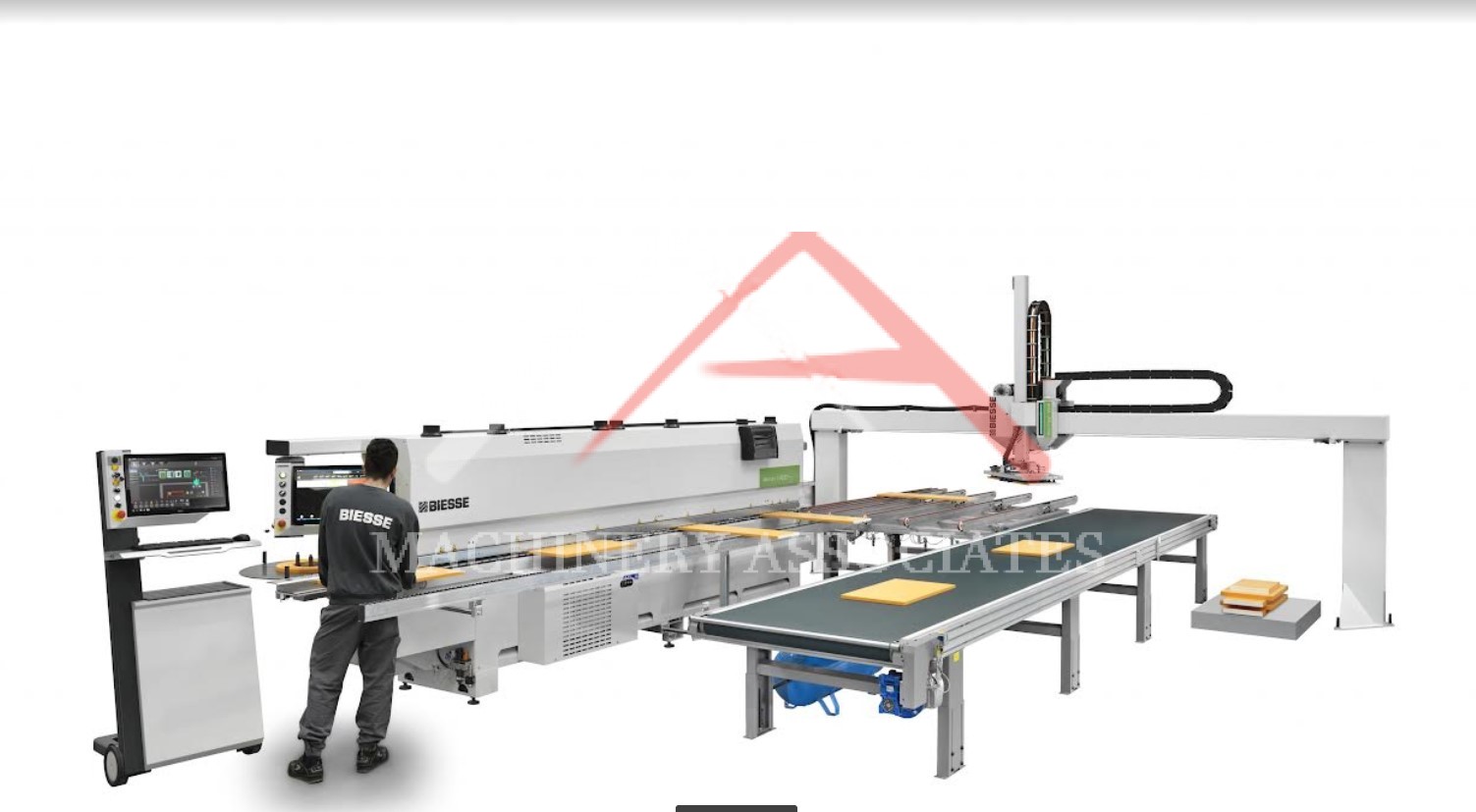

Biesse Stream A 6.0 w/ Winner W4 Return/Stack System

A rare to the market machine. This low hour machine is $480,000 new!! Just serviced and installed fresh PUR rebuilt gluepots.

| MA ID: | EBS - 13624 |

| Status: | Sold |

| Price: | Call for Price |

| Category: |

Edgebanders -Single Sided |

| Manufacturer: | Biesse |

| Model: | Stream 6.0 w/Winner W4 |

| Year of Manufacture: | 2018 |

| Condition: | Very Good |

| Electric: | Multi Voltage 60 Cycle 3 Phase |

|

2018 Biesse Stream A 6.0 with Winner W-4 Return/Stacker System

CALL FOR AVAILABILITY This system is currently selling new at $480,000! System was de-commissioned by Biesse. The machine was a repossession and has sat in storage since 2019, due to litigation and (COVID). It has moved to our Hudson, NH facility for cleaning and the install of newly rebuilt Gluepots. The machinery will be available Sept 15. We will have new photos at that time. Biesse "Stream A 6.0" with Winner "W4" Stacker and Return System Biesse "Stream A 6.0" Edgebander 10 - 60 mm panel height 10 - 35/60 mm panel height with corner rounding (depends on profile) 14 - 64 mm edgebanding height 0.4 - 3 mm coiled banding thickness 0.4 - 22 mm strip banding thickness 25 mm panel protrusion from track 140 mm (5.5") minimum panel length 95 mm (3.7") minimum panel width (150 mm length) 70 mm (2.8") minimum panel width (250 mm length)

Features; Bottom feed track, (Variable speed 12/18/20/25 mpm) Top pressure belt Motorized positioning of top beam PC control (Dell) Smart-Touch 21.5 numerical control Windows operating system Sintra HD software 21.5" color monitor Standard keyboard and mouse Integrated hard drive, USB port Two (4) position edgebanding magazine additional to the traditional "Pie Plate" Automatic edge feeding systems for coils or strips 3 mm maximum coiled banding thickness Lighted sound enclosure Outboard roller support Automatic lubrication system

Stream Layout; Infeed fence with panel spacer w/on-screen adjustment Premill unit with two (2) motors 4.7 HP, 12000 rpm ea.) Guillotine for cutting coiled banding Anti-adhesive unit Infrared heating lamp Tekno glue system with roller Pre-melt hopper for PUR adhesive Quick-change glue pot, 6.6 pound capacity Bi-directional glue roller Dual thermostat Automatic temperature reduction when machine is idle Compatible with EVA or Polyurethane adhesives

Pressure unit One (1) driven roller Five (5) idle rollers, 60 mm/2.4" diameter

Two (2) motor end trim unit (High Speed option) 0.8 HP, 12000 RPM 0 - 25 degree vertical incline, automatic rotation Three (3) pneumatic positions

Top/bottom rough trim unit 12,000 RPM Can be tilted up to 1 degree Two (2) position pneumatic exclusion Four (4) NC axes driven by brushless motors and ball screws

Top/bottom fine trim unit 12,000 RPM 0 - 45 degree tilt Pneumatic exclusion Pro Nest Lubrication unit to enhance corner rounding finished appearance

Two (2) motor corner round unit 12,000 RPM NC adjustment Pneumatic exclusion

Top/bottom profile scrape unit with external collection box NC adjustment Pneumatic exclusion Pro Nest

Top/bottom flat scrape unit Pneumatic exclusion Air blowers

Top/bottom buff unit 0.5 HP, 2800 RPM Tiltable Misting unit Hot air blower Comes with; Multitap electrical transformer

Biesse "Winner W4" Stacker 2,500 mm/98" maximum panel length 250 mm/9.8" minimum panel length 1,000 mm/39.3" maximum panel width 100 mm/3.9" minimum panel width 60 mm/2.4" maximum panel thickness 10 mm/0.4" minimum panel thickenss 154 pound maximum weight 10 cycles/min. for panel returning 8 cycles/min. for panel stacking 800 mm/31.5" maximum stack height (on pallet on floor) Overhead pneumatic stacker Bridge support Aluminum plate with suction cups Transfer table with left reference Beckhoff PLC Safety fencing and photo barrier External electrical transformer

Return conveyor Belt return conveyor Two (2) sections Air floatation tables |

|

Some photos may show tooling. Tooling is never included in the listing unless otherwise noted in the description.

Please confirm all data before committing to a purchase.

*Subject to credit approval. Additional programs available.