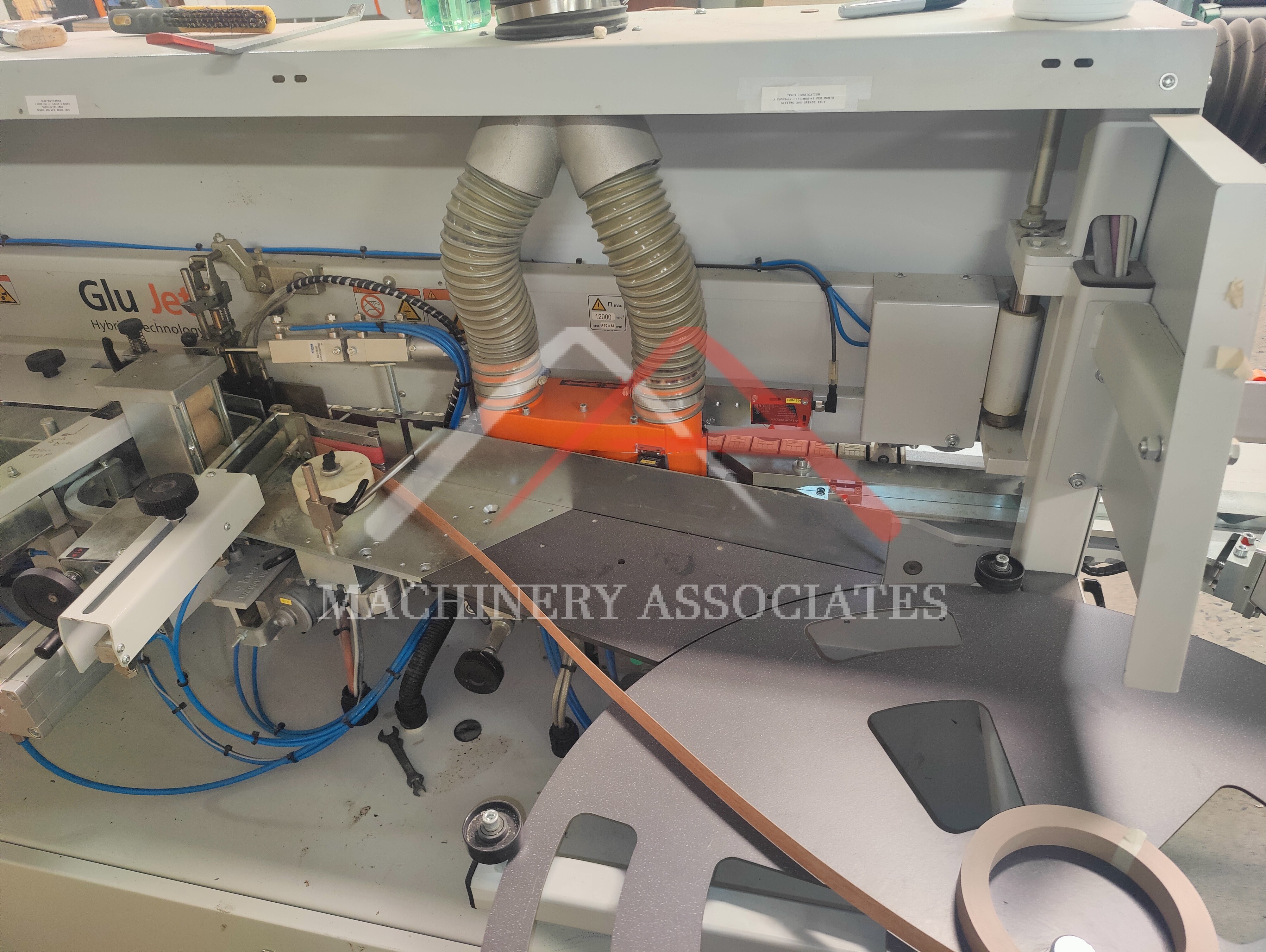

Holzher 1329 Edgebander

A very well kept machine in Great condition. The 1329 is the fully servo controlled machine you've been looking for.

| MA ID: | EBS - 13051 |

| Status: | Sold |

| Price: | Call for Price |

| Category: |

Edgebanders -Single Sided |

| Manufacturer: | HolzHer |

| Model: | Sprint 1329 |

| Year of Manufacture: | 2017 |

| Condition: | Very Good |

| Electric: | 230 Voltage 60 Cycle 3 Phase |

|

2017 Holzher 1329 Edgebander

Contract Pending Machine Layout Pre-Milling Station; (2) 2.0 KW (2.68 HP) - 12,000 RPM motors; Equipped with "ProLock" quick-change flange including height adjustment for optimum utilization of cutters. Edge Feeder Magazine: "SYNCRO" drive. The new magazine with its synchronous adaptation to the feed rate guarantees short intervals between work pieces & simultaneously optimizes edging protrusions. Small 3° feed angle thanks to nozzle design with easy feeding of coils, strips &up to 3 mm & solid wood edging up to 15 mm (.059"). A "Tractor-Belt feed System", edge guide equipped with automatic guillotine lock-out for safety. GLUING SYSTEM: "Glue Jet" thin film technology processes "EVA" or "PUR" Glue, motorized, programmable glue nozzle (upper glue line) height positioning. Pressure Section: Servo controlled pressure section with (1) large driven roller and (2) cantered idle rollers. Straight and tapered pressure rollers for perfect glued joints. End Trimming Unit: Front & rear (2) 0.35 KW (0.5 HP) - 9,000 RPM motor, uni-point swivel-axis for no re-indexing when changing from flush to bevel end trim (0° - 10° bevel),"PCS" programmable pneumatic change-over from flush to bevel. Multi-function Trimming Unit: Servo controlled Tilt and Servo controlled in/out, .65 KW (0.87 HP) - 12,000 RPM each motor. Uni-Point design, pneumatic. Trimming & Corner Rounding Unit: For linear edge-trimming or vertical corner rounding with servo motor programmable positioning, (2) Motor 0.22 KW (0.30 HP) - 9000 RPM for up to 3 mm edge thickness and work-piece thickness min./max. 8 - 60 mm (0.31 - 2.36"), max. feed speed 18 MPM (60 FMP) up to 25 mm panel thickness, (16 m/min. 38 mm thickness, 12/m/min. 60 mm thickness). Profile Scraping Unit: Servo controlled knife position for PVC edges, reversible insert carbide knives, equipped with air-jet blowers and chip collector box. Glue Scraping Unit: Flat, top/bottom, ball bearing guided and pneumatic controlled. Buffing Station: Top & bottom buffing motors with 150 mm ( 6.0") cloth buffing wheel diameter, adjusts in any direction (vertical tilt is 0° - 5°, horizontal swivel is 0° - 20°); 1,440 RPM wheel rotation.

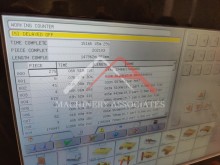

Specifications Edgebanding Capacity: edge thickness min./max. 0.4 - 15 mm (0.016 - 0.59"), coiled material 0.4 - 3 mm (0.016 - 0.157"); Panel thickness 8 - 60 mm (0.236 - 2.362"), workpiece width min. of 60 mm (2.36"); workpiece length min. 160 mm (6.29"); Feed speed 10 - 18 MPM (33 - 59 FPM). Programmable Logic Control (PLC) for Pre-Milling, edge feed, glue application, end trimming, flush trimming, radius trimming, scraping & corner rounding. Holz-Her PPC 315 "EDGE CONTROL TOUCH" Electronically controlled set-up processes with 100% repetition accuracy. Edgebander can be operated manually when required, without necessity to write a program. |

|

| Shipping Footprint: |

19 (length) x 4 (width) x

5 (height)

|

| Weight: | 4000 lbs |

Some photos may show tooling. Tooling is never included in the listing unless otherwise noted in the description.

Please confirm all data before committing to a purchase.

*Subject to credit approval. Additional programs available.